Glass tempering furnace also known as glass tempering machine, glass tempering equipment, glass toughening machine, etc. It uses physical or chemical method to form the press stress on glass surface and tensile stress formed within the glass layer. When glass is subject to external forces, the compressive stress layer can offset part of the tensile stress, avoid glass breaking, so as to achieve the purpose of improving the strength of the glass. In addition, the microcracks on the glass surface become more subtle under this compressive stress, which also improves the strength of the glass to some extent.

The current physical toughened method is widely used heating the glass to softening point (650 ℃), the glass still can maintain its original shape, but has certain ability to migration of particles in the glass, structural adjustment, so that the internal stress of the existence of eliminate soon, then put the glass tempering furnace for toughened glass blowing quench, when the temperature balance, The glass surface produces compressive stress, the inner layer produces tensile stress, that is, the glass produces a uniform and regular distribution of internal stress, improve the tensile strength of glass as a brittle material, so that the glass resistance to bending and impact strength is improved. At the same time, due to the existence of uniform stress inside the glass, once the local glass is damaged by the impact that exceeds its strength, it will explode into small particles under the action of internal stress, which improves its safety. Therefore, toughened glass can also be called prestressed glass or safety glass.

In the process of glass tempering furnace, generally, wind and stress, the wind is in the process of cooling due to uneven due to uneven glass stress, which formed in some special Angle will see the glass surface is observed under light and dark and white stripes. Stress spots are also caused by stress imbalance, such as in the heating process, there is a temperature difference between the furnace side and the middle of the stress imbalance. Stress spots cannot be completely avoided, but well-designed tempering equipment can minimize the visibility of stress spots.

According to the heating mode characteristics of equipment, the equipment can be divided into the forced convection heating tempered glass tempering machine and radiation heating glass tempering furnace; If it is divided according to the finished glass shape, it can be divided into flat glass tempering furnace and bend glass tempering furnace or flat & bend glass tempering furnace. continuous tempering equipment, two-way tempering equipment, combined tempering equipment, unequal arc bending tempering equipment, hanging furnace and so on.

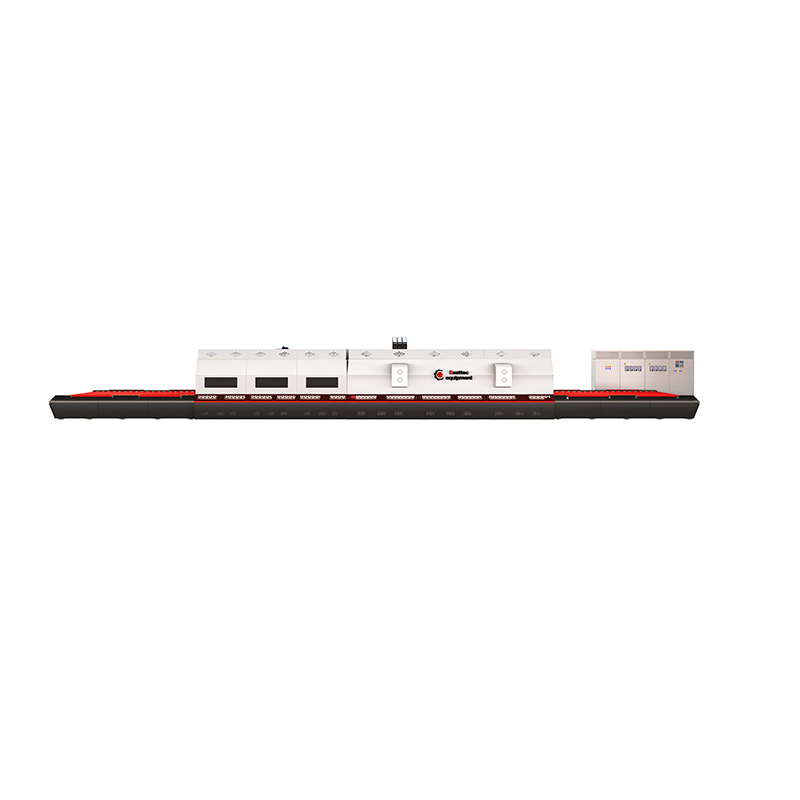

Easttec glass tempering furnace, with almost 30 years’ experience, technology since 1994.